Chemical Engineering Design Principles Practice and Economics of Plant and Process Design

Second Edition

Gavin Towler

Ray Sinnott

Preface to the Second Edition

This book was originally written by Ray Sinnott as Volume 6 of the “Chemical Engineering” series

edited by Coulson and Richardson. It was intended to be a standalone design textbook for undergraduate

design projects that would supplement the other volumes in the Coulson and Richardson

series. In 2008 we published the first edition of Chemical Engineering Design: Principles, Practice

and Economics of Plant and Process Design as an adaptation of Coulson and Richardson Volume 6

for the North American market. Some older sections of the book were updated and references to

laws, codes, and standards were changed to an American rather than British basis; however, the

general layout and philosophy of the book remained unaltered.

The first edition of this book was widely adopted and I received a great deal of valuable feedback

from colleagues on both the strengths and weaknesses of the text in the context of a typical

North American undergraduate curriculum. The experiences and frustrations of my students at

Northwestern University and comments from coworkers at UOP also helped suggest areas where

the book could be improved. The changes that have been made in this second edition are my

attempt to make the book more valuable to students and industrial practitioners by incorporating

new material to address obvious gaps, while eliminating some material that was dated or repetitive

of foundation classes.

The main change that I have made is to rearrange the order in which material is presented to fit

better with a typical two-course senior design sequence. The book is now divided into two parts.

Part I: Process Design covers the topics that are typically taught in a lecture class. The broad

themes of Part I are flowsheet development, economic analysis, safety and environmental impact,

and optimization. Part II: Plant Design contains chapters on equipment design and selection that can

be used as supplements to a lecture course. These chapters contain step-by-step methods for designing

most unit operations, together with many worked examples, and should become essential references

for students when they begin working through their design projects or face design problems

early in their industrial career.

The coverage of process flowsheet development has been significantly increased in this edition.

The introductory chapters on material and energy balances have been deleted and replaced with

chapters on flowsheet development and energy recovery, which lead into the discussion of process

simulation. The treatment of process economics has also been increased, with new chapters on capital

cost estimating and operating costs, as well as a longer discussion of economic analysis and sensitivity

analysis. The section on optimization is now presented as a separate chapter at the end of Part I,

as most instructors felt that it was more logical to present this topic after introducing economic

analysis and the constraints that come from safety and environmental considerations.

Part II begins with an overview of common themes in equipment design. This is followed by the

chapter on pressure vessel design, which underpins the design of most process vessels. The follow-

ing chapters then proceed through reactors, separation processes, solids handling, heat exchange,

and hydraulic equipment. My experience has been that students often struggle to make the connection

from reaction engineering fundamentals to a realistic mechanical layout of a reactor, so a new

chapter on reactor design has been added, with a focus on the practical aspects of reactor specification.

The coverage of separation processes has been expanded to include adsorption, membrane separations, chromatography, and ion exchange. The treatment of solids-handling processes has also

been increased and solids-handling operations have been grouped together in a new chapter.

Throughout the book I have attempted to increase the emphasis on batch processing, revamp

designs, and design of biological processes, including fermentation and the separations commonly

used in product recovery and purification from biochemical processes. Almost every chapter now

contains examples of food, pharmaceutical, and biological processes and operations. Many graduating

chemical engineers in the United States will find themselves working in established plants where they

are more likely to work on revamp projects than new grassroots designs. A general discussion of

revamp design is given in Part I and examples of rating calculations for revamps are presented

throughout Part II.

Chemical engineers work in a very diverse set of industries and many of these industries have

their own design conventions and specialized equipment. I have attempted to include examples and

problems from a broad range of process industries, but where space or my lack of expertise in the

subject has limited coverage of a particular topic, references to specialized texts are provided.

This book draws on Ray Sinnott’s and my experience of the industrial practice of process

design, as well as our experience teaching design at the University of Wales Swansea, University of

Manchester, and Northwestern University. Since the book is intended to be used in practice and not

just as a textbook, our aim has been to describe the tools and methods that are most widely used in

industrial process design. We have deliberately avoided describing idealized conceptual methods

that have not yet gained wide currency in industry. The reader can find good descriptions of these

methods in the research literature and in more academic textbooks.

Standards and codes of practice are an essential part of engineering and the relevant North

American standards are cited. The codes and practices covered by these standards will be applicable

to other countries. They will be covered by equivalent national standards in most developed countries,

and in some cases the relevant British, European, or international standards have also been

cited. Brief summaries of important U.S. and Canadian safety and environmental legislation have

been given in the relevant chapters. The design engineer should always refer to the original source

references of laws, standards, and codes of practice, as they are updated frequently.

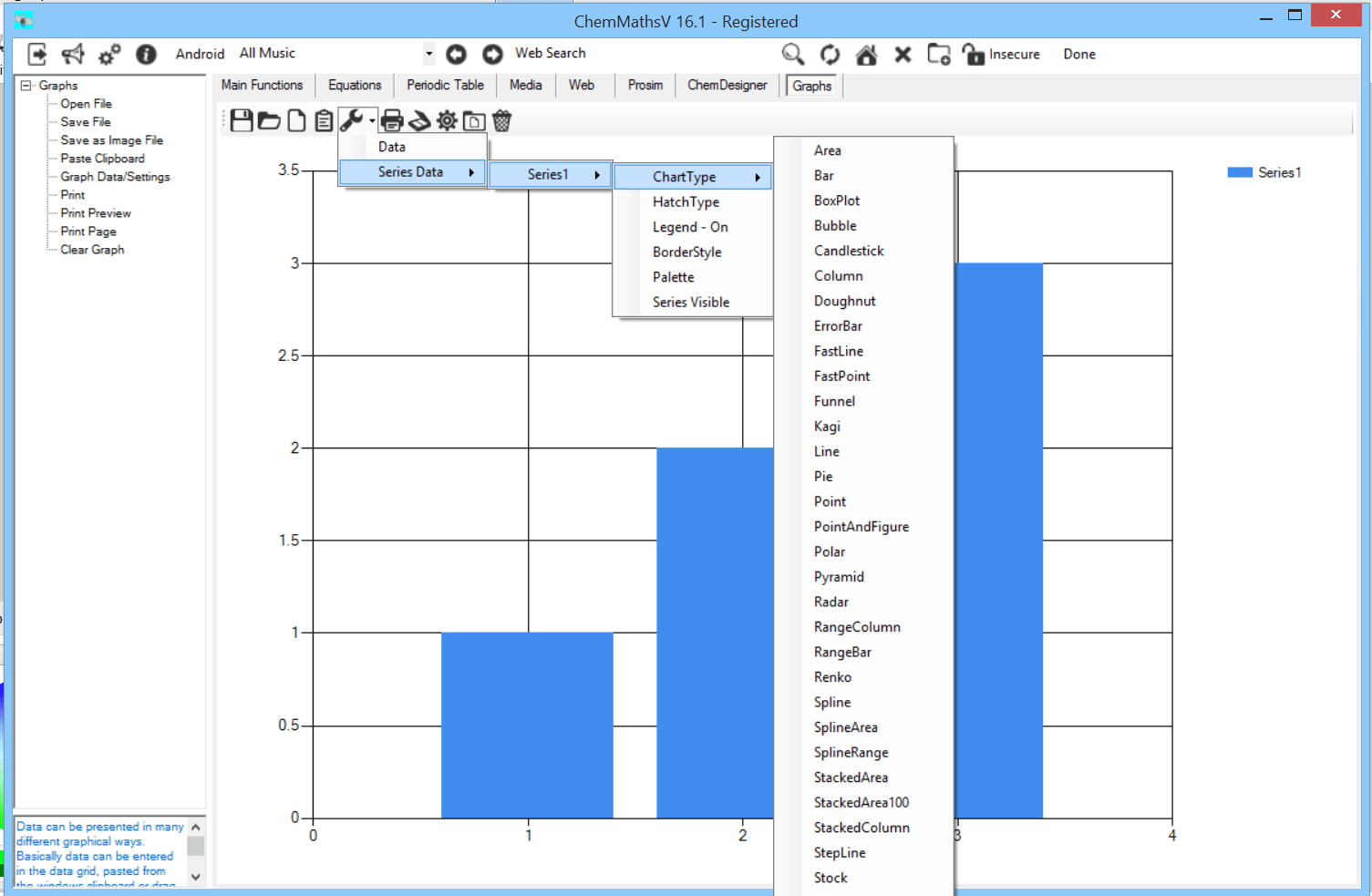

Most industrial process design is carried out using commercial design software. Extensive reference

has been made to commercial process and equipment design software throughout the book.

Many of the commercial software vendors provide licenses of their software for educational purposes

at nominal fees. I strongly believe that students should be introduced to commercial software

at as early a stage in their education as possible. The use of academic design and costing software

should be discouraged. Academic programs usually lack the quality control and support required by

industry, and the student is unlikely to use such software after graduation. All computer-aided

design tools must be used with some discretion and engineering judgment on the part of the

designer. This judgment mainly comes with experience, but I have tried to provide helpful tips on

how to best use computer tools.