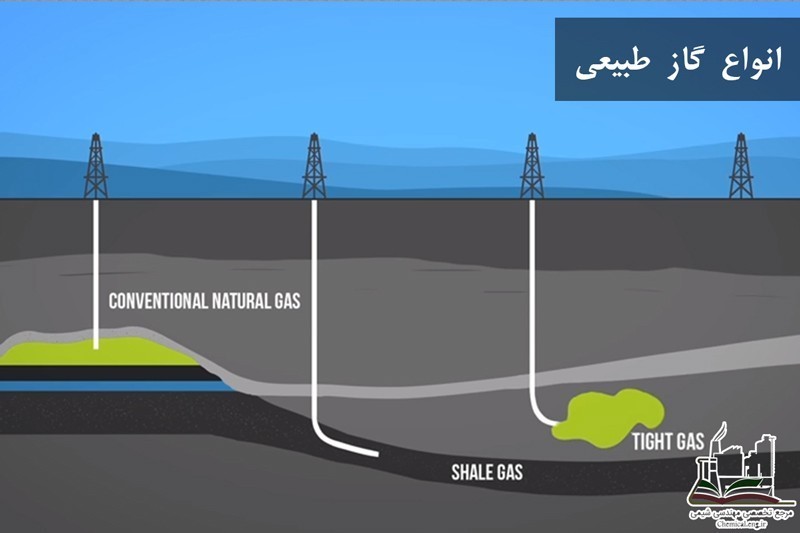

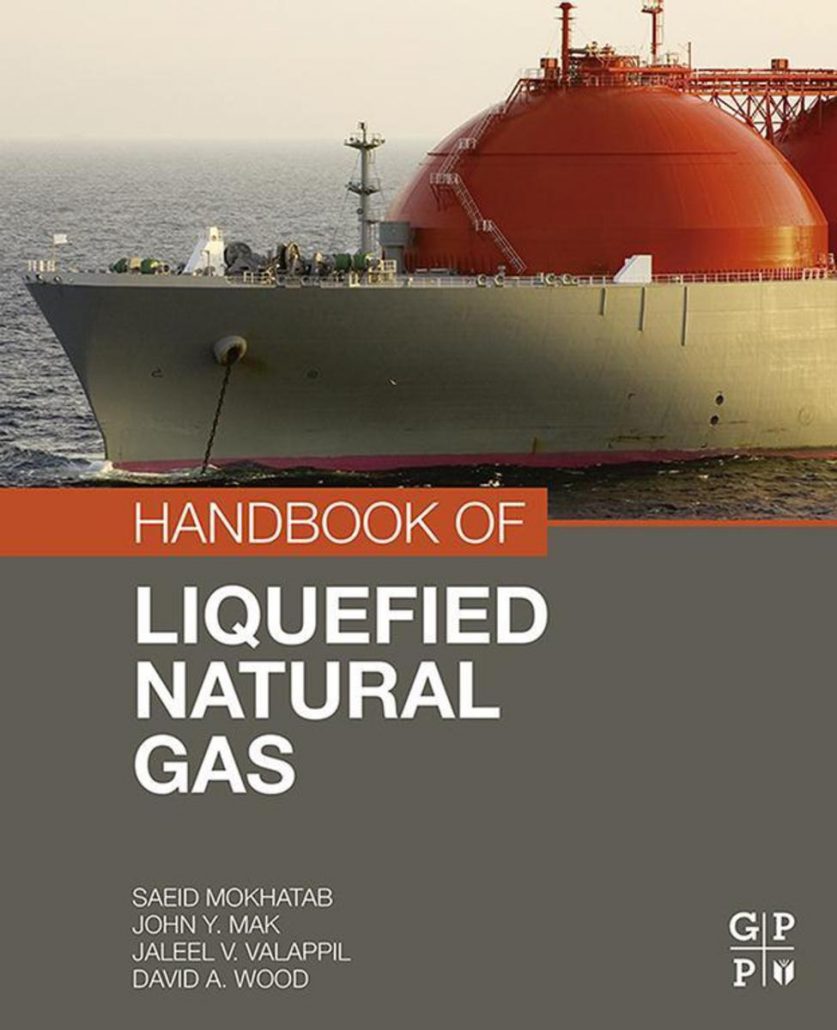

گاز طبیعی مایع یا الانجی (به انگلیسی: Liquefied natural gas) به گاز طبیعیای اطلاق میشود که موقتاً برای ذخیرهسازی یا حملونقل در حجم زیاد به حالت مایع تبدیل شده است.

الانجی حجمی معادل ۱/۶۰۰ حجم گاز طبیعی در حالت گازی را داراست. گاز مایع، بیبو، بیرنگ، غیر سمی و غیر خورنده است. خطراتی که این گاز می تواند در پی داشته باشد شامل شعلهورشدن، انجماد و خفگی میباشد. چُگالی انرژی الانجی ۶۰ درصد سوخت دیزل میباشد.

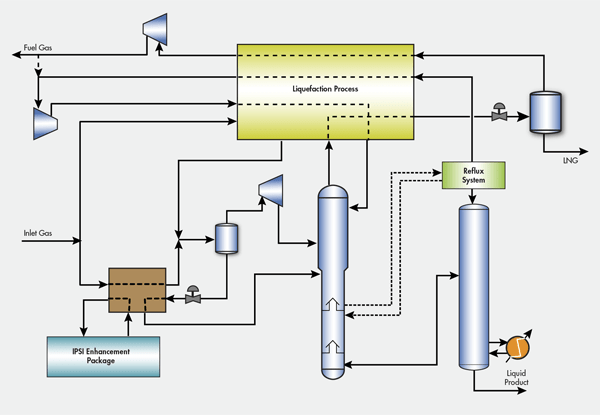

فرآیند میعان شامل حذف ترکیبات خاصی همچون گردوغبار، گازهای اسیدی، هلیوم، آب و هیدروکربنهای سنگین است که در جریان روبهپایین،(انتقال گاز در لولهها) برای گاز دچار مشکل مینمایند. گاز طبیعی را بعد از حذف موارد فوق در فشاری معادل فشار اتمسفر و دمای ۱۶۲- درجه سانتیگراد سرد میکنند.(حداکثر فشار گاز برای کاربردهای انتقال در فشاری معادل ۲۵ کیلو پاسکال یا ۳٫۶ پیاسآی است).

LNG (گاز طبیعی مایع شده)

کاهش حجم گاز در شرایطی که خطوط لوله در دسترس نمیباشد، باعث صرفهجویی اقتصادی در مسیرهای بلند میشود. در مواردی که انتقال گاز طبیعی از طریق خط لوله اقتصادی یا عملیاتی نیست، میتوان آن را از طریق کشتیهای دریایی تانکر گاز مایع، که مخصوص اینکار طراحی شدهاند و یا تانکرهای جادهای، حمل نمود.

در بازارهای مصرف، الانجی مجدداً به حالت گاز در میآید. چگالی الانجی، تقریباً از ۰٫۴۱ تا ۰٫۵ کیلوگرم بر لیتر، متغیر است، که تابعی از دما، فشار و ترکیبات آن میباشد. مقدار گرمایش الانجی در بالاترین سطح، در دمای ۱۶۴- درجه سلسیوس به ۲۴ مگاژول بر لیتر میرسد. کمترین میزان گرمایش الانجی ۲۱ مگاژولبرلیتر است.

الانجی، عمدتاً شامل متان (بیش از ۹۰ درصد) و مقادیر کمی اتان، پروپان، بوتان و برخی از آلکانهای سنگین دیگر می باشد. فرآیند پالایش الانجی، میتواند به نحوی طراحی شود، که محصول نهایی تولید شده شامل ۱۰۰ درصد متان باشد.

BASICS

LNG, or liquefied natural gas, is natural gas that is cooled to -260° Fahrenheit until it becomes a liquid and then stored at essentially atmospheric pressure. Converting natural gas to LNG, a process that reduces its volume by about 600 times – similar to reducing the volume of a beach ball to the volume of a ping-pong ball – allows it to be transported internationally via cargo ships. Once delivered to its destination in the U.S. or abroad, the LNG is warmed back into its original gaseous state so that it can be used just like existing natural gas supplies, by sending it through pipelines for distribution to homes and businesses

When returned to its gaseous state, LNG is used across the residential, commercial and industrial sectors for purposes as diverse as heating and cooling homes, cooking, generating electricity and manufacturing paper, metal, glass and other materials. LNG is also increasingly being used to fuel heavy-duty vehicles

Clean burning natural gas is used to heat and cool over half of all American homes and power 23 percent of the nation’s electricity. Even though America has an abundance of natural gas, LNG is essential to providing the U.S. with the ability to import or export natural gas depending on market conditions

SAFETY/SECURITY

LNG HAS A PROVEN SAFETY RECORD

The LNG industry’s highest priority has always been safety and security, which is reflected in the industry’s enviable safety record. LNG is not stored under pressure and it is not explosive. Although a large amount of energy is stored in LNG, it cannot be released rapidly enough if released into the open environment to cause the overpressures associated with an explosion. LNG vapors (methane) mixed with air are not explosive in an unconfined environment. A major incident resulting in a large release of LNG could result in a fire, but only if there is the right concentration of LNG vapor in the air (5% – 15%) and a source of ignition

The LNG industry provides appropriate security, planning, prevention and risk mitigation in close coordination with local, state, and federal authorities, including the U.S. Coast Guard. These measures significantly reduce risks from intentional events such as terrorist acts

SHIP SAFETY

More than 135,000 LNG carrier voyages have taken place without major accidents or safety or security problems, either in port or at sea. (The International Group of Liquefied Natural Gas Importers (GIIGNL) – 2011)

LNG ships are double-hulled, with more than six feet of void space or water ballast between the outer and inner hulls and the cargo tanks. The double hulls help to prevent leakage or rupture in the event of an accident. LNG ships are also equipped with sophisticated leak detection technology, emergency shutdown systems, advanced radar and positioning systems, and numerous other technologies designed to ensure the safe and secure transport of LNG

The U.S. Coast Guard determines the suitability of every LNG ship that delivers cargoes into and out of the U.S. through a rigorous annual inspection. If a ship fails the inspection, all deficiencies must be fixed before it can unload its cargo or leave the country. LNG ships are issued a Certificate of Compliance by the Coast Guard to state that they are in complete compliance with U.S. regulations.

Studies undertaken by various technical authorities and Sandia National Laboratories on LNG shipping safety and security confirm that risks from accidental LNG spills, including as a result of collisions and groundings, are highly unlikely due to the rigorous safety policies and practices put in place by the LNG industry. Risks resulting from intentional events, such as terrorist acts, can be greatly reduced with appropriate security, planning, mitigation, and prevention. The industry has these precautions in place

SECURITY

The LNG industry carefully follows requirements set forth by the International Maritime Organization, Federal Energy Regulatory Commission, Department of Transportation, and the U.S. Coast Guard and works closely with the Department of Homeland Security to ensure that its operations are safe and secure.

LNG ships are fast for their size and less prone to pirate attacks since they sit high in the water relative to crude oil carriers and conventional cargo ships. The industry takes piracy seriously and follows international best practices. There are additional security measures, procedures, and equipment on board LNG tankers to deter and repel such attacks, but they are not disclosed in order to increase their effectiveness

Before a ship enters a U.S. port, the captain is required to inspect each and every compartment and report this inspection as part of the 96-hour notice. This written inspection is given to the U.S. Coast Guard upon arrival in U.S. waters. The Coast Guard may then perform its own inspection. There are other security procedures in place when the vessel is at sea, which are also not disclosed to ensure their effectiveness

Every crew member must either have a visa that has been approved by the U.S. State Department, or the ship has to have an armed guard to prevent crew members without visas from disembarking. The crew list is provided to the U.S. Coast Guard 96 hours prior to arrival. A background check is run on all crew members by the Coast Guard and U.S. Immigration and Security Authorities

TERMINAL SAFETY

LNG import and export terminals are designed with multiple layers of protection and must meet rigorous safety regulations. They are equipped with spill containment systems, fire protection systems, multiple gas, flame, smoke and low- and high-temperature detectors and alarms, automatic and manual shut-down systems, video surveillance systems, and highly trained personnel

The U.S. Coast Guard determines the suitability of a waterway to transport LNG safely and creates safety and security rules for each specific port. The Coast Guard works with terminal and ship operators and host port authorities to ensure that policies and procedures conform to required standards and works with operators to conduct emergency response drills. The U.S. Coast Guard has the authority to require and receive background checks of crews, conduct ship searches and may require the use of Sea Marshals, who are specially trained and armed U.S. Coast Guard personnel

LIQUEFACTION FACILITY SAFETY

Liquefaction of natural gas to LNG requires cooling the natural gas until it becomes a liquid. These processes include gas conditioning before liquefaction, processing and managing the impurities and liquid hydrocarbons, and storage and handling of the refrigerants that are used to cool the natural gas to a liquid state.

The refrigerants used in the LNG process typically consist of some combination of the following light hydrocarbons: methane, ethane, ethylene, propane, butane and isopentane. Nitrogen is also a common refrigerant component

Refrigerants used in natural gas liquefaction plants are safely produced and handled routinely in hundreds of refineries, petrochemical plants and natural gas processing facilities across the United States and world

Methane, ethane, propane and butane are normal components of natural gas. Natural gas and its components are also widely and safely used as commercial products by industries, businesses, farms and residences. For example, propane is commonly used in home cooking grills and for heating purposes

Natural gas liquefaction facilities must comply with rigorous government regulations and industry codes and standards for its engineering, operations, maintenance and personnel training

The liquefaction process requires significant compression systems for refrigeration that include large centrifugal compressors typically driven by gas turbines, steam turbines or large electric motors. This type of rotating equipment is larger than typically found in LNG import terminals and is similar to what is found in refineries, power plants and large chemical plants. Rigorous measures are utilized at liquefaction facilities to ensure the safe design and operation of this equipment

ENVIRONMENT

LNG IS A SAFE, ENVIRONMENTALLY-FRIENDLY FUEL

Natural gas is the cleanest burning fossil fuel and is being used throughout the world to reduce carbon dioxide emissions. Compared to coal, natural gas produces far fewer carbon dioxide emissions and sulfur emissions. LNG is simply natural gas in a liquid state. As a fuel, LNG produces relatively low emissions when burned to heat and cool homes, generate electricity, and power vehicles

LNG is odorless, non-toxic and non-corrosive. When exposed to the environment, LNG rapidly evaporates, leaving no residue on water or soil. If spilled, LNG would not result in a slick because 100 percent of it evaporates, leaving no residue behind

LNG CONTRIBUTES TO A CLEANER GLOBAL ENVIRONMENT

Sending clean-burning natural gas into the international marketplace helps countries around the globe meet clean air quality standards, which contributes to worldwide efforts to reduce greenhouse gas emissions as more and more coal-fired electricity will be replaced with natural gas. This is particularly beneficial in countries where access to clean energy is otherwise limited

PACE STUDY SERVES AS A MODEL FOR GLOBAL EFFORTS TO REDUCE AIR POLLUTION

A 2009 independent study commissioned by CLNG and performed by Pace Global Energy Services found that existing U.S. coal fired power generation produces more than double the lifecycle greenhouse gas emissions than power generation fueled by regasified LNG.

[Study looked at GHG emissions from natural gas production, liquefaction, shipping, regasification, pipeline transportation and use at a power plant and compared to GHG emissions from coal mining, transportation and use at a power plant]

Other Pace Study Key Findings:

Even the cleanest coal technologies produce 70 percent more lifecycle greenhouse gas emissions than power generated by regasified LNG

Replacing just one 500 megawatt coal-fired power plant with LNG fueled power generation for one year would equate to taking 557,000 cars off the roads

The PACE study provides a transparent “apples to apples” comparison of the lifecycle greenhouse gas emissions attributable to LNG and coal. The analysis uses a representative average of typical U.S. LNG and coal operations used for generation of electricity. This includes a natural gas power plant supplied by LNG, a current U.S. coal fired power plant, and two advanced coal technologies not yet commercially viable in the U.S — Integrated Gasification Combined Cycle (IGCC) and Advanced Ultra Super Critical Coal (SCPC