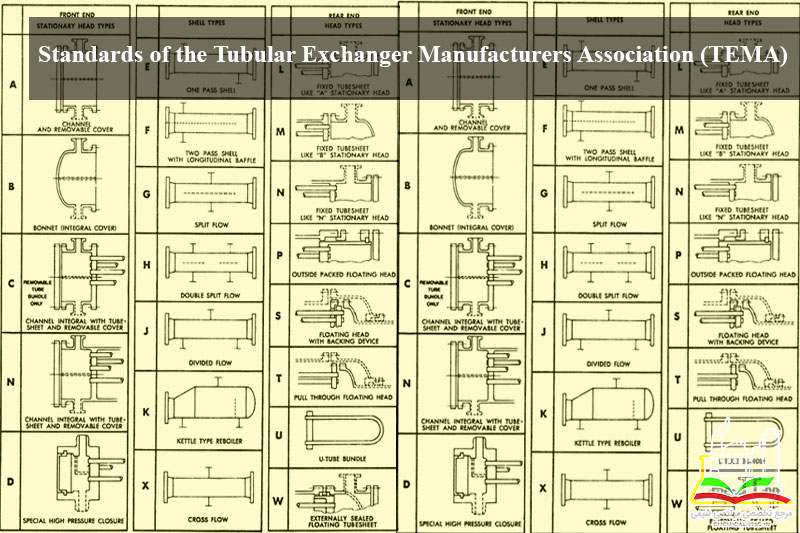

STANDARDS of The Tubular Exchanger Manufacturers Association (TEMA) 10 edition (2019)

Section CONTENTS Page

MEMBERSHIP LIST iii

TECHNICAL COMMITTEE iv

PREFACE

NOTES TO USERS viii

NOMENCLATURE

1 Size Numbering and Type Designation—Recommended Practice 1-1

2 Nomenclature of Heat Exchanger Components 1-3

2 F FABRICATION TOLERANCES

1 External Dimensions, Nozzle and Support Locations 2-1

2 Recommended Fabrication Tolerances 2-2

3 Tubesheets, Partitions, Covers, and Flanges 2-3

4 Flange Face Permissible Imperfections 2-3

5 Peripheral Gasket Surface Flatness 2-3

3 G GENERAL FABRICATION AND PERFORMANCE INFORMATION

1 Shop Operation 3-4

2 Inspection 3-4

3 Nameplates 3-4

4 Drawings and Code Data Reports 3-4

5 Guarantees 3-5

6 Preparation of Heat Exchangers for Shipment 3-6

7 General Construction Features of TEMA Standard Heat Exchangers 3-7

4 E INSTALLATION, OPERATION, AND MAINTENANCE

1 Performance of Heat Exchangers 4-1

2 Installation of Heat Exchangers 4-1

3 Operation of Heat Exchangers 4-2

4 Maintenance of Heat Exchangers 4-4

5 Changes to Configuration of Heat Exchangers 4-8

5 RCB MECHANICAL STANDARDS TEMA CLASS RCB HEAT EXCHANGERS

1 Scope and General Requirements 5.1-1

2 Tubes 5.2-1

3 Shells and Shell Covers 5.3-1

4 Baffles and Support Plates 5.4-1

5 Floating End Construction 5.5-1

6 Gaskets 5.6-1

7 Tubesheets 5.7-1

8 Flexible Shell Elements 5.8-1

9 Channels, Covers, and Bonnets 5.9-1

10 Nozzles 5.10-1

11 End Flanges and Bolting 5.11-1

6 V FLOW INDUCED VIBRATION

1 Scope and General 6-1

2 Vibration Damage Patterns 6-1

3 Failure Regions 6-1

4 Dimensionless Numbers 6-2

5 Natural Frequency 6-3

6 Axial Tube Stress 6-10

7 Effective Tube Mass 6-10

8 Damping 6-13

6 V FLOW INDUCED VIBRATION (continued)

9 Shell Side Velocity Distribution 6-15

10 Estimate of Critical Flow Velocity 6-18

11 Vibration Amplitude 6-20

12 Acoustic Vibration 6-21

13 Design Considerations 6-25

14 Selected References 6-27

7 T THERMAL RELATIONS

1 Scope and Basic Relations 7-1

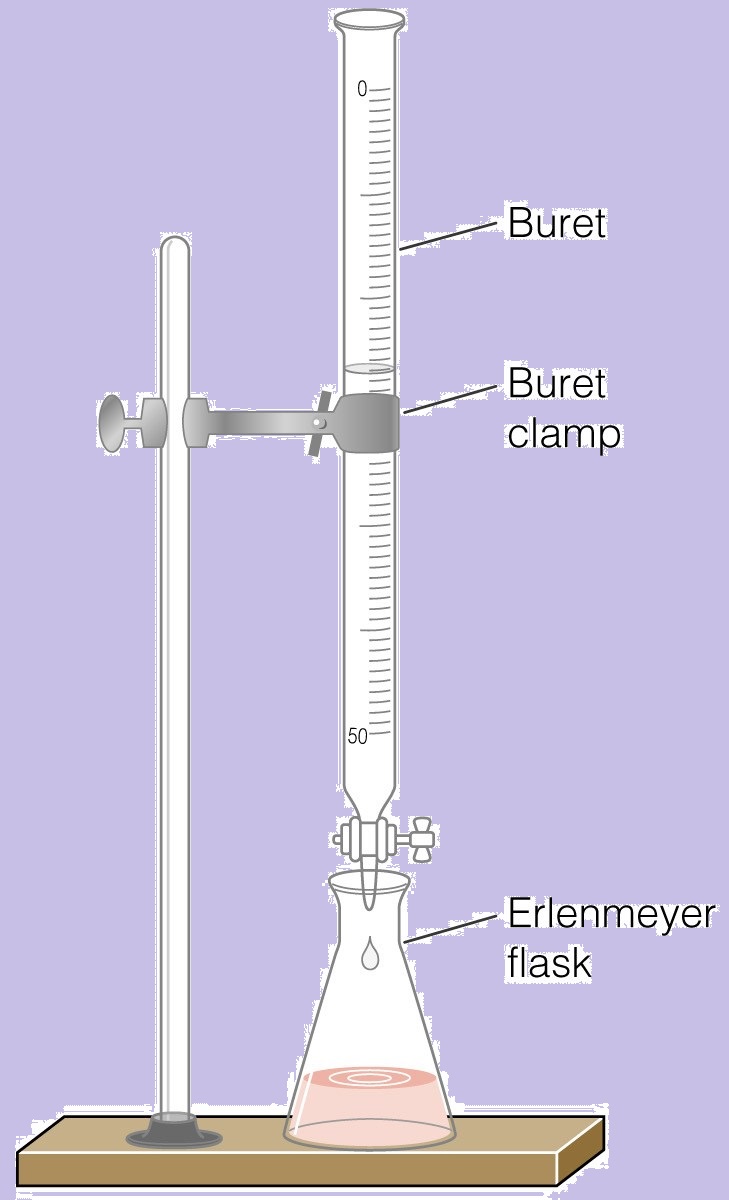

2 Fouling 7-2

3 Fluid Temperature Relations 7-3

4 Mean Metal Temperatures of Shell and Tubes 7-5

8 P PHYSICAL PROPERTIES OF FLUIDS

1 Fluid Density 8-1

2 Specific Heat 8-1

3 Heat Content 8-2

4 Thermal Conductivity 8-2

5 Viscosity 8-2

6 Critical Properties 8-3

7 Properties of Gas and Vapor Mixtures 8-3

8 Selected References 8-4

D GENERAL INFORMATION

(See detailed Table of Contents) 9-1

10 RGP RECOMMENDED GOOD PRACTICE

G-7.1.1 Horizontal Vessel Supports 10-2

G-7.1.2 Vertical Vessel Supports 10-17

G-7.2 Lifting Lugs 10-22

G-7.3 Wind and Seismic Design 10-24

RCB-2 Plugging Tubes in Tube Bundles 10-24

RCB-4 Entrance and Exit Areas 10-24

RCB-7 Tubesheets 10-31

RCB-10.6 Nozzle Loadings 10-32

RCB-11.5 Flange Design 10-32

RCB-12 Finite Element Analysis Guidelines 10-33

T-2 Fouling 10-34

Appendix A — Tubesheets A-1

INDEX Index